Features of DGT Reducer

1. Compact Structure

Planetary Gear Reducer is characterized by full utilization of space, designing bearings and gear ratio in a limited space, so that the product is smaller and more space-saving than traditional reducers.

2. High Efficiency

When the planetary gear set is running, it will be in a completely tight meshing state, which reduces the situation of gear collision or gear damage caused by partial meshing.

The characteristic of complete tight meshing allows the efficiency loss of each gear transmission only 3%.

This type of transmission mode can ensure that the kinetic energy is input to the reducer and then to the mechanism end, while maintaining high transmission efficiency and preventing mechanical loss caused by friction and slippage of internal gears.

3. High Axial Radial Load Capacity

The reducer output shaft from Pin Hong Technology adopts a style of large span, so that the bearing is arranged at both ends of the output shaft.

This design can effectively disperse the force acting on the out put shaft and reduce the load of the bearing.

In other words, the product of the same size has increased load capacity in axial radial direction.

4. High Strength

The gear set of the reducer is very strong and stable, and the thickness of the gear disperses the load acting on the gear. The large-span bearing set provides a stable structure;

The precision gear set distributes the load to each planetary gear under tight meshing to withstand the torque load.

With this design, Pin Hong can provide better products to the market.

5. High Stability

The precision machining of Pin Hong Technology ensures that the products are coaxial and concentric, and the bearing designed with a large span provides the product with excellent stability.

Drawings of DGT Reducer

Parameters of DGT Reducer

| Size | DGT060 | DGT075 | DGT100 | DGT140 | DGT180 | DGT220 | |

|---|---|---|---|---|---|---|---|

| D1 | 68 | 85 | 120 | 165 | 215 | 250 | |

| D2 | 5.2 | 6.8 | 8.6 | 10.5 | 13 | 17 | |

| ※D3 | 16 | 22 | 32 | 40 | 55 | 75 | |

| D4 | 60 | 70 | 90 | 130 | 160 | 180 | |

| D5 | 20 | 35 | 65 | 55 | 70 | 80 | |

| C1 | 48.5 | 56 | 65 | 112 | 112 | 138 | |

| C2 | 18.5 | 18 | 12 | 27 | 27 | 30 | |

| C3 | 28.5 | 36 | 51 | 82 | 82 | 105 | |

| C4 | 2 | 3 | 5 | 5 | 6 | 7 | |

| C5 | 25 | 32 | 40 | 65 | 70 | 90 | |

| C6 | 62 | 76 | 115 | 142 | 180 | 220 | |

| C7 | 6 | 7 | 20 | 12 | 15 | 20 | |

| C8 | L1 | 80.5 | 103 | 125.5 | 146.5 | 188 | 197 |

| L2 | 102.5 | 129 | 155.5 | 184.5 | 228 | 247 | |

| C9 | 20 | 25.5 | 25.5 | 34.5 | 35 | 44.5 | |

| C10 | 13 | 18 | 18 | 22.5 | 23 | 28.5 | |

| L | L1 | 149 | 184.5 | 216 | 293 | 330 | 379.5 |

| L2 | 171 | 210.5 | 246 | 331 | 375 | 429.5 | |

| M | M5XP0.8X12.5 | M8XP1.25X20 | M12XP1.75X30 | M16XP2.0X40 | M20XP2.5X50 | M5XP02.5X50 | |

| K1 | 5 | 6 | 10 | 12 | 16 | 20 | |

| K2 | 18 | 24.5 | 35 | 43 | 59 | 79.5 | |

| d | ≤19 | ≤24 | ≤32 | ≤38 | ≤55 | ≤55 | |

| △A | 50 | 80 | 110 | 130 | 160 | 200 | |

| B | 6 | 10 | 10 | 10 | 11 | 12 | |

| △F | ≤33.5 | ≤46 | ≤53 | ≤66 | ≤82.5 | ≤88.5 | |

| Size | Stage | Ratios | DGT060 | DGT075 | DGT100 | DGT140 | DGT180 | DGT220 |

|---|---|---|---|---|---|---|---|---|

| Rated output torque(Nm) | 1 | 3 | 55 | 130 | 208 | 342 | 588 | 1140 |

| 4 | 50 | 140 | 290 | 542 | 1050 | 1700 | ||

| 5 | 60 | 160 | 330 | 650 | 1200 | 2000 | ||

| 6 | 55 | 150 | 310 | 600 | 1100 | 1900 | ||

| 7 | 50 | 140 | 300 | 550 | 1100 | 1800 | ||

| 8 | 43 | 114 | 247 | 475 | 950 | 1520 | ||

| 10 | 40 | 100 | 230 | 450 | 900 | 1500 | ||

| 2 | 9 | 55 | 130 | 208 | 342 | 588 | 1140 | |

| 12 | 50 | 140 | 290 | 542 | 1050 | 1700 | ||

| 15 | 55 | 130 | 208 | 342 | 588 | 1140 | ||

| 16 | 50 | 140 | 290 | 542 | 1050 | 1700 | ||

| 20 | 50 | 140 | 290 | 542 | 1050 | 1700 | ||

| 25 | 60 | 160 | 330 | 650 | 1200 | 2000 | ||

| 28 | 50 | 140 | 300 | 550 | 1100 | 1800 | ||

| 30 | 55 | 150 | 310 | 600 | 1100 | 1900 | ||

| 32 | 43 | 114 | 247 | 475 | 950 | 1520 | ||

| 35 | 50 | 140 | 300 | 550 | 1100 | 1800 | ||

| 40 | 43 | 114 | 247 | 475 | 950 | 1520 | ||

| 50 | 60 | 160 | 330 | 650 | 1200 | 2000 | ||

| 60 | 55 | 150 | 310 | 600 | 1100 | 1900 | ||

| 70 | 50 | 140 | 300 | 550 | 1100 | 1800 | ||

| 80 | 43 | 114 | 247 | 475 | 950 | 1520 | ||

| 100 | 40 | 100 | 230 | 450 | 900 | 1500 | ||

| Max output torque(Nm) | 1,2 | 3~100 | 3.0 times Batedoatpat torque | |||||

| Return backlash(arcmin) | 1 | 3~10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| 2 | 9~100 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | |

| Rated input speed(rpm)) | 1,2 | 3~100 | 5000 | 4000 | 4000 | 3000 | 3000 | 2000 |

| Max input speed(rpm) | 10000 | 8000 | 8000 | 6000 | 6000 | 4000 | ||

| Weight (kg) | 1 | 3~10 | 1.6 | 4.2 | 8.3 | 17 | 33 | 51 |

| 2 | 9~100 | 2.4 | 6 | 10 | 21 | 40 | 71 | |

| Torsional stiffness(Nm/arcmin) | 1,2 | 3~100 | 5 | 10 | 20 | 50 | 140 | 230 |

| Allowable Radial Load(N) | 3000 | 5000 | 6000 | 13000 | 20000 | 36000 | ||

| Allowable axial load(N) | 4000 | 6000 | 8000 | 15000 | 21000 | 38000 | ||

| Noise(dB) | ≤58 | ≤60 | ≤63 | ≤65 | ≤67 | ≤70 | ||

| Life(hrs) | 20000 | |||||||

| Efficency(%) | 1 | 3~10 | ≥97 | |||||

| 2 | 9~100 | ≥94 | ||||||

| Temperature(°C) | 1,2 | 3~100 | -10℃~+90℃ | |||||

| Degree of protection | IP64 | |||||||

| Grease | Fully Synthetic Grease | |||||||

| Moment of inertia(kg.cm) | 1 | 3 | 0.16 | 0.61 | 3.25 | 9.21 | 28.98 | 69.61 |

| 4 | 0.14 | 0.48 | 2.74 | 7.54 | 23.67 | 54.37 | ||

| 5 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 53.27 | ||

| 6 | 0.13 | 0.45 | 2.65 | 7.25 | 22.75 | 51.72 | ||

| 7 | 0.13 | 0.45 | 2.62 | 7.14 | 22.48 | 50.97 | ||

| 8 | 0.13 | 0.44 | 2.58 | 7.07 | 22.59 | 50.84 | ||

| 10 | 0.13 | 0.44 | 2.57 | 7.03 | 22.14 | 50.56 | ||

| 2 | 9 | 0.16 | 0.61 | 3.25 | 9.21 | 28.98 | 69.61 | |

| 12 | 0.16 | 0.61 | 3.25 | 9.21 | 28.98 | 69.61 | ||

| 15 | 0.16 | 0.61 | 3.25 | 9.21 | 28.98 | 69.61 | ||

| 16 | 0.14 | 0.48 | 2.74 | 7.54 | 23.67 | 54.27 | ||

| 20 | 0.14 | 0.48 | 2.74 | 7.54 | 23.67 | 54.27 | ||

| 25 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 53.27 | ||

| 28 | 0.14 | 0.48 | 2.74 | 7.54 | 23.67 | 54.37 | ||

| 30 | 0.16 | 0.61 | 3.25 | 9.21 | 28.98 | 69.61 | ||

| 32 | 0.14 | 0.48 | 2.74 | 7.54 | 23.67 | 54.37 | ||

| 35 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 53.27 | ||

| 40 | 0.14 | 0.48 | 2.74 | 7.54 | 23.67 | 54.37 | ||

| 50 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 53.27 | ||

| 60 | 0.13 | 0.45 | 2.65 | 7.25 | 22.75 | 51.72 | ||

| 70 | 0.13 | 0.45 | 2.62 | 7.14 | 22.48 | 50.97 | ||

| 80 | 0.13 | 0.44 | 2.58 | 7.07 | 22.59 | 50.84 | ||

| 100 | 0.13 | 0.44 | 2.57 | 7.03 | 22.14 | 50.56 | ||

Application Industry

Suitable for a wide range of applications

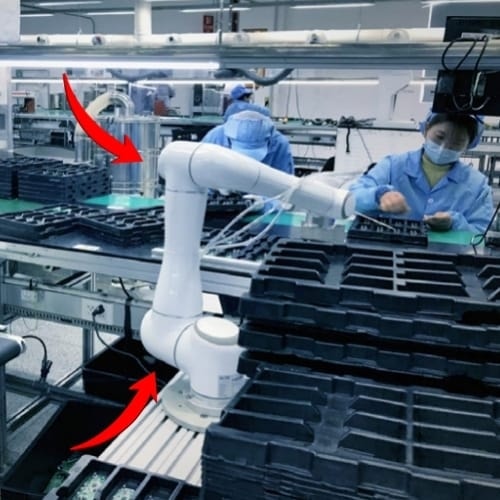

Cooperative Robot

Multi-articular machine

Laser Cutting Machine

Machine tool,Grinding mach-ines

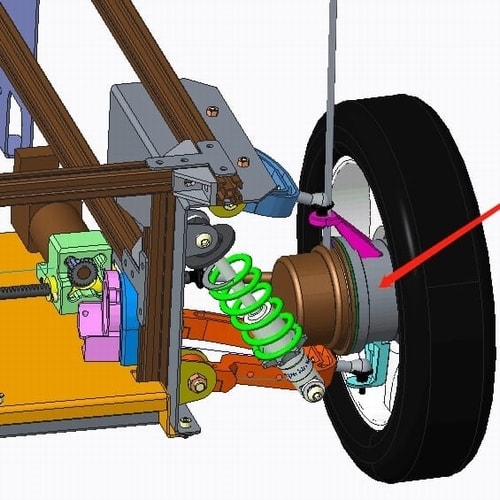

PARALLEL MANIPULATOR

Scara robots,spider hand...

INDUSTRIAL ROBOT

Manipulator,axis robot etc

HUMANOID ROBOT

Bionic robot,walking robots

AGV CAE

Warehouse logistics AGV car

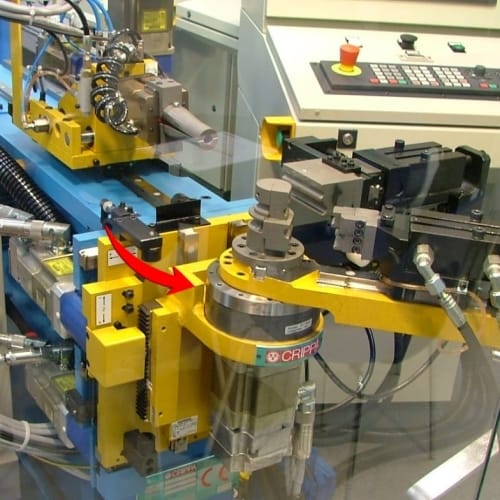

MACHINE TOOL

Pipe bending machine...

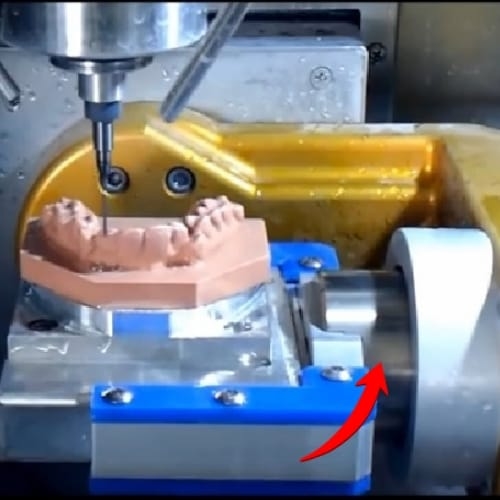

CNC Carving Machine

Denture carving and printing

EXTERNAL ROBOTS

rehabilitation bobot...

Factories of Fubao Mechanic Tech

English

English Deutsch

Deutsch Русский

Русский Español

Español

Quote Now