WF series reducer

WF series reducer represents a wide range precision reduction gears with flange shaped case.

WF series high-precision reduction gears consist of an accurate reduction mechanism and high-capacity radial and axial cylindrical bearings.

This design of gears allows the mounting of the load directly to the output flange or case without requigears are characterized by a modular design, lt can be directly connected to any servo brand motor.

Advantages of WF series reducer

- High rigidity

- High precision

- High torque

- Small size

- Efficient

- Long lifetime

- Easy assembly

Characteristics of WF series reducer

| Features of WF series reducer | |

|---|---|

| Case | a. threaded holes in case b. threaded and through holes in case |

| Input shaft design | Input shaft offers following versions: a. shaft with key-way b. according to special request |

| Installation and operation characteristics | A wide range of modular configurations |

Ordering specifications of WF series reducer

| WF | 17 | 51 | A | B |

|---|---|---|---|---|

| Name | Size | Ratio | Input | Output |

| WF | 07 | Reference rating table | a. Key input b. Hold on to input |

a. Axis output b. Flange output |

| 17 | ||||

| 25 | ||||

| 32 | ||||

| 40 |

Rating table of WF series reducer

| Size | Reduction ratio |

Rated Output Torque |

Opening and stopping allowable moment |

Instantaneous admissible moment |

Reted input speed |

Max input speed |

Inclination stiffness |

Torsional stiffness |

No-load startup moment |

Driving Accuracy |

Backlash accuracy |

Inertial moment |

Weight | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Axis rotation |

Shell Rotation |

Nm | Nm | Nm | rpm | rpm | Nm/arcmin | Nm/arcmin | Nm | arcmin | arcmin | Kg-m2 | Kg | |

| WF07 | 21 | 20 | 15 | 30 | 45 | 3000 | 6000 | 6 | 1.1 | 0.12 | P1≤±1 P2≤±3 |

P1≤±1 P2≤±3 |

0.52 | 0.42 |

| 41 | 40 | 0.11 | 0.47 | |||||||||||

| WF17 | 21 | 20 | 50 | 100 | 150 | 3000 | 6000 | 28 | 6 | 0.21 | P1≤±1 P2≤±3 |

P1≤±1 P2≤±3 |

0.88 | 0.85 |

| 41 | 40 | 0.18 | 0.72 | |||||||||||

| 61 | 60 | 0.14 | 0.69 | |||||||||||

| WF25 | 21 | 20 | 110 | 220 | 330 | 3000 | 5500 | 131 | 24 | 0.47 | P1≤±1 P2≤±3 |

P1≤±1 P2≤±3 |

6.12 | 2 |

| 31 | 30 | 0.41 | 5.67 | |||||||||||

| 41 | 40 | 0.38 | 4.9 | |||||||||||

| 51 | 50 | 0.35 | 4.56 | |||||||||||

| 81 | 80 | 0.31 | 4.25 | |||||||||||

| WF32 | 25 | 24 | 190 | 380 | 570 | 3000 | 4500 | 240 | 35 | 1.15 | P1≤±1 P2≤±3 |

P1≤±1 P2≤±3 |

11 | 4.2 |

| 31 | 30 | 1.1 | 10.8 | |||||||||||

| 51 | 50 | 0.77 | 9.35 | |||||||||||

| 81 | 80 | 0.74 | 8.32 | |||||||||||

| 101 | 100 | 0.6 | 7.7 | |||||||||||

| WF40 | 25 | 24 | 320 | 640 | 960 | 3000 | 4000 | 377 | 50 | 1.35 | P1≤±1 P2≤±3 |

P1≤±1 P2≤±3 |

13.2 | 6.6 |

| 31 | 30 | 1.32 | 12.96 | |||||||||||

| 51 | 50 | 0.92 | 11.22 | |||||||||||

| 81 | 80 | 0.81 | 9.84 | |||||||||||

| 121 | 120 | 0.72 | 8.4 | |||||||||||

WF series reducer drawings

General information of reducer

The Fubao high precision reduction gears are based on a new reduction mechanism and a new design of a radial-axial output bearing. As a result,they represent a new generation of power transmission systems. This new transmission concept allows the use of the Fubao reduction gear directly in robot joints, rotary tables, and wheel gears in various transport systems.

Fubao high precision reduction gears are designed for applications requiring a high reduction ratio, high kinematic accuracy, low lost motion, high moment capacity and high stiffness of a compact design with a limited installation zone, and low mass.

Operating principle of RV reducer

The basic parts of FubaoDRIVE high precision reduction gear are show in Fig.

-

Case of reducer

At the same time incorporates the high capacity precision radial, axial output bearing integrated in the reduction gear.

-

Flanges of reducer

Input and out put flanges are fixed together by pin shafts, and rotate at reduced speed in the radial-axial output bearing relative to the case.

-

Input shaft

High-speed member of the reduction mechanism carried by bearing in the flanges. The shaft eccentrics rotationally support the trochoidal gears via bearings.

-

Trochoidal gears

Their almost 50% simultaneously meshing trochoidal teeth transmit a very high torque which ensures power, performance and accuracy of the reduction gear.

Functional advantages of RV reducer

-

Micro-structure

By adopting differential deceleration mechanism and thin cross roller bearing, achieving ultra-flat shape and contributing to compact size of equipment. Small size and unparalleled excellent parameters are combined to achieve the best ratio of performance, price and size.

-

Exceptional precision

Complex meshing through precision hypocycloid gears and high precision hobbing, achieving higher transmission accuracy. At the same time, small size and large speed ratio are maintained.

-

High rigidity

Because of increasing meshing rate and disperse load, the rigidity is very high.

-

High overload capacity

Excellent parameters of tilting and torsional stiffness at the same time with keeping of trouble-free operation under exceptionally low noise and low vibrations. Relyon high resistance and overload capacity of reduction gear with integrated radial-axial bearings that is guaranteed to you by us at various temperature ranges of application environment.

-

Easy installation of motor

It can be installed directly for any brand of motor without adding any device.

-

Maintenance free

Seal in grease to achieve maintenance-free. Don't need to add lubricating grease later, no installation direction restriction.

-

Technical support

Our professional team of experts are ready to solve any problems for you. The manufacturing process of high-wear resistant materials and high precision parts are certified by lSO9000 quality system, which is also the basic premise for reliable operation of products.

Installation process of RV reducer

Before the installation, it is desirable to wipe off the protective oil film from the surface of the reduction gear by a clean and dry cloth.Contact surfaces of friction joints must be degreased prior to the installation.

When cleaning, make sure that the grease doesn't get into the reduction gear.

During the installation, proceed with following steps:

First, fasten a coupling to the reduction gear, then the connecting flange, to which mount the motor and then bolt the whole assembly to the frame.

Reduction gear is most often used in combination with a pre-stage, which may comprise gears or toothed belt drives. The driven pulley is attached to the shaft of the reduction gear with screws which have to be tightened with a tightening torque according.

Connection of a toothed pulley with the reduction gear shaft by means of a screw connection.

Connection of a toothed pulley with the reduction gear shaft by means of a screw connection. Connection of a toothed pulley with the reduction gear shaft by means of a friction connection.

Connection of a toothed pulley with the reduction gear shaft by means of a friction connection. Connection of a gear wheel with the reduction gear shaft by means of a screw connection.

Connection of a gear wheel with the reduction gear shaft by means of a screw connection.Application Industry

Suitable for a wide range of applications

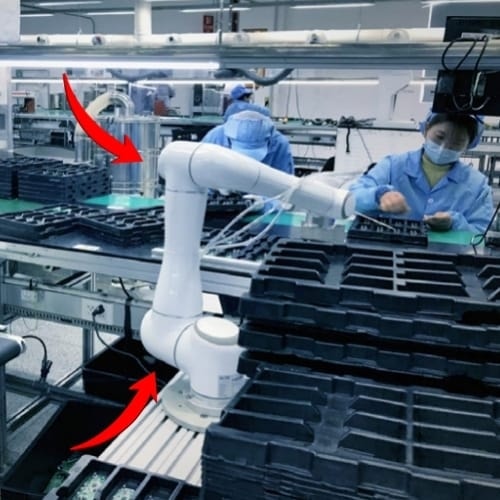

Cooperative Robot

Multi-articular machine

Laser Cutting Machine

Machine tool,Grinding mach-ines

PARALLEL MANIPULATOR

Scara robots,spider hand...

INDUSTRIAL ROBOT

Manipulator,axis robot etc

HUMANOID ROBOT

Bionic robot,walking robots

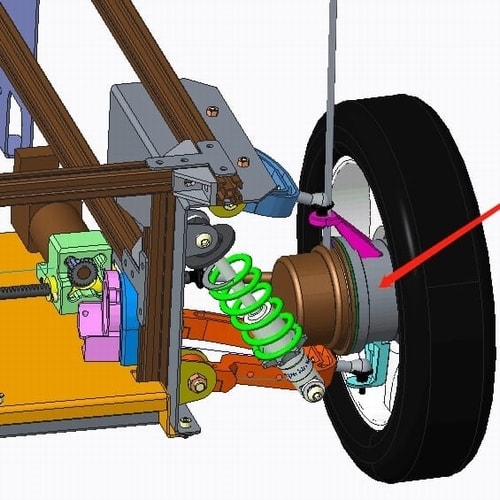

AGV CAE

Warehouse logistics AGV car

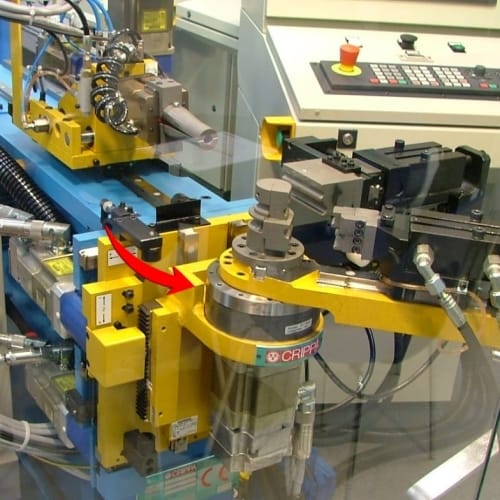

MACHINE TOOL

Pipe bending machine...

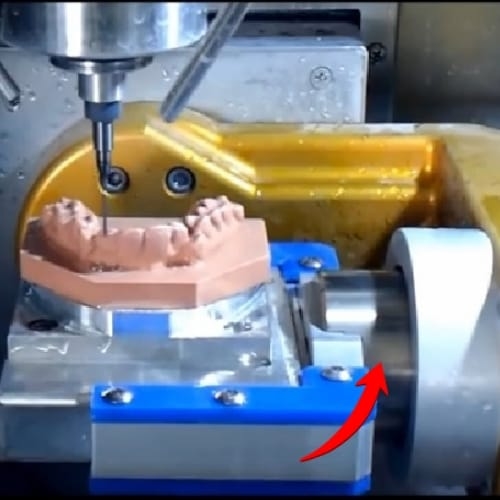

CNC Carving Machine

Denture carving and printing

EXTERNAL ROBOTS

rehabilitation bobot...

Factories of Fubao Mechanic Tech

English

English Deutsch

Deutsch Русский

Русский Español

Español

Quote Now