Features of WABR series planetary reducer

The gearbox is made of high-quality alloy steel, which has been treated with carbon-nitriding to obtain the best wear resistance and impact resistance toughness. The finite element analysis of the gearbox strength is carried out by using ANSYS technology, and the tooth surface shape and lead are trimmed at the same time to reduce the impact and noise of gearbox meshing and increase the service life of the gear train.

The output planet carrier adopts an integrated (double support) structure design, and the front and rear bearings are distributed in the box with a large span to form a stable integrated structure to ensure high torsional rigidity and precision.

The ring gearbox and the output housing adopt an integrated design, made of high-quality steel, and formed by hot forging to obtain high material density.

The integrated design can ensure that all geometric dimensions are processed at one time, and it has higher precision and strength compared with other built-in and clip-on structures. The input shaft and locking device adopt an integrated design, and the double bolts are symmetrically distributed to achieve dynamic balance.

At the same time, the strong locking of the double bolts effectively prevents the electric shaft from slipping and realizes high-precision and low-backlash power transmission.

The gearbox is made of high-quality alloy steel, which has been treated with carbon-nitriding to obtain the best wear resistance and impact resistance toughness. The finite element analysis of the gearbox strength is carried out by using ANSYS technology, and the tooth surface shape and lead are trimmed at the same time to reduce the impact and noise of gearbox meshing and increase the service life of the gear train.

The output planet carrier adopts an integrated (double support) structure design, and the front and rear bearings are distributed in the box with a large span to form a stable integrated structure to ensure high torsional rigidity and precision.

Drawings of WABR series planetary reducer

Parameters of WABR series planetary reducer

| Size | WABR042 | WABR060 | WABR090 | WABR115 | WABR142 | WABR180 | WABR220 | |

|---|---|---|---|---|---|---|---|---|

| D1 | 50 | 70 | 100 | 130 | 165 | 215 | 250 | |

| D2 | 3.4 | 5.5 | 6.5 | 9 | 10.5 | 13 | 17 | |

| D3h6 | 13 | 16 | 22 | 32 | 40 | 55 | 75 | |

| D4g6 | 35 | 50 | 80 | 110 | 130 | 160 | 180 | |

| D5 | 16.5 | 24.5 | 34.5 | 34.5 | 48 | 65 | 95 | |

| D6 | M4X0.7P | M5X0.8P | M8X1.25P | M12X1.75P | M16X2P | M20X2.5P | M20X2.5P | |

| L1 | 42.6 | 60 | 90 | 115 | 142 | 180 | 220 | |

| L2 | 26 | 37 | 48 | 65 | 97 | 105 | 138 | |

| L3 | 5 | 7 | 10 | 12 | 15 | 20 | 30 | |

| L4 | 5 | 8 | 10 | 10 | 18 | 15 | 20 | |

| L5 | 20 | 28.5 | 35.5 | 51 | 79 | 82 | 105 | |

| L6 | 2 | 3 | 3 | 5 | 5 | 6 | 7 | |

| L7 | 16 | 20 | 30 | 40 | 63 | 70 | 90 | |

| L8 | 4.5 | 4.8 | 7.2 | 10 | 12 | 15 | 15 | |

| L9 | 10 | 12.5 | 19 | 28 | 36 | 42 | 42 | |

| C1* | 46 | 70 | 90 | 145 | 200 | 200 | 200 | |

| C2* | M4X0.7P | M5X0.8P | M6X1P | M8X1.25P | M12X1.75P | M12X1.75P | M12X1.75P | |

| C3* | 8 | 14 | 19≤C3≤22 | 19≤C3≤24 | 22≤C3≤42 | 22≤C3≤42 | 22≤C3≤42 | |

| C4* | 27 | 32.5 | 47 | 67 | 82 | 118 | 119 | |

| C5* | 30 | 50 | 70 | 110 | 114.3 | 114.3 | 114.3 | |

| C6* | 5 | 5 | 5 | 10 | 10 | 10 | 10 | |

| C7* | 42.6 | 60 | 90 | 130 | 180 | 180 | 220 | |

| C9* | 53.25 | 68 | 97 | 126 | 150 | 205.5 | 224 | |

| C10* | 74.5 | 98 | 142 | 183.5 | 221 | 276.5 | 334 | |

| B1 | 5 | 5 | 6 | 10 | 12 | 16 | 20 | |

| H1 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79.5 | |

| C8* | L1 | 108 | 146.5 | 200.5 | 265 | 356 | 387.5 | 494.5 |

| L2 | 128 | 166.5 | 228.5 | 302 | 420 | 446 | 510 | |

| Size | Stage | Ratios | WABR042 | WABR060 | WABR090 | WABR115 | WABR142 | WABR180 | WABR220 |

|---|---|---|---|---|---|---|---|---|---|

| Rated output torque(Nm) | L1 | 3 | 19 | 53 | 145 | 290 | 520 | 950 | 1550 |

| 4 | 20 | 55 | 150 | 300 | 550 | 1000 | 1650 | ||

| 5 | 17 | 54 | 140 | 290 | 530 | 1050 | 1700 | ||

| 6 | 19 | 53 | 145 | 290 | 520 | 950 | 1550 | ||

| 7 | 14 | 44 | 125 | 270 | 450 | 960 | 1500 | ||

| 8 | 20 | 55 | 150 | 300 | 550 | 1000 | 1650 | ||

| 9 | 11 | 37 | 95 | 220 | 360 | 950 | 1550 | ||

| 10 | 11 | 37 | 95 | 220 | 360 | 1050 | 1700 | ||

| 14 | 14 | 44 | 125 | 271 | 450 | 960 | 1500 | ||

| 18 | 11 | 37 | 95 | 220 | 360 | 800 | 1250 | ||

| 20 | 11 | 37 | 95 | 220 | 360 | 800 | 1250 | ||

| 12 | 19 | 53 | 145 | 290 | 520 | 950 | 1550 | ||

| 15 | 19 | 53 | 145 | 290 | 520 | 950 | 1550 | ||

| 20 | 20 | 55 | 150 | 300 | 550 | 1000 | 1650 | ||

| 25 | 17 | 54 | 140 | 290 | 530 | 1050 | 1700 | ||

| 30 | 19 | 53 | 145 | 290 | 520 | 950 | 1550 | ||

| 35 | 17 | 54 | 140 | 290 | 530 | 1050 | 1700 | ||

| L2 | 40 | 20 | 55 | 150 | 300 | 550 | 1000 | 1650 | |

| 45 | 17 | 54 | 140 | 290 | 630 | —— | —— | ||

| 50 | 17 | 54 | 140 | 290 | 530 | 1050 | 1700 | ||

| 70 | 17 | 54 | 140 | 290 | 530 | 1050 | 1700 | ||

| 90 | 17 | 54 | 140 | 290 | 530 | — | — | ||

| 100 | 17 | 54 | 140 | 290 | 530 | 1050 | 1700 | ||

| Max instantaneous output torque(Nm) | L1, L2 | 3 times rated output torque | |||||||

| Return backlashP0(arcmin) | L1 | 3~10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| L2 | 12~100 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | |

| Return backlashP1(arcmin) | L1 | 3~10 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 |

| L2 | 12~100 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | |

| Return backlashP2(arcmin) | L1 | 3~10 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 |

| L2 | 12~100 | ≤12 | ≤12 | ≤12 | ≤12 | ≤12 | ≤12 | ≤12 | |

| Rated input speed(rpm) | L1, L2 | 3~100 | 5000 | 3000 | 3000 | 3000 | 3000 | 1500 | 1500 |

| Max input speed(rpm) | L1, L2 | 3~100 | 10000 | 6000 | 6000 | 6000 | 6000 | 3000 | 3000 |

| Torsional stiffness(Nm/arcmin) | L1, L2 | 3~100 | 2.5 | 6 | 12 | 23 | 45 | 148 | 220 |

| Allowable radial Load(N) | L1, L2 | 3~100 | 515 | 1010 | 1780 | 3420 | 5380 | 8330 | 11120 |

| Allowable axial load(N) | L1, L2 | 3~100 | 410 | 600 | 1500 | 2650 | 4670 | 6460 | 8560 |

| Noise(dB) | L1, L2 | 3~100 | 62 | 63 | 65 | 70 | 70 | 73 | 75 |

| Life(hrs) | L1, L2 | 3~100 | 20,000(10,000 continue operating) | ||||||

| Efficiency at full load(%) | L1 | 3~10 | ≥97% | ||||||

| L2 | 12~100 | ≥94% | |||||||

| Temperature(°c) | L1, L2 | 3~10 | -10℃~+90℃ | ||||||

| Weight(KG) | L1 | 3~10 | 1 | 1.3 | 3.5 | 7.8 | 16.1 | 30 | 58 |

| L2 | 12~100 | 1.4 | 2 | 5.6 | 9.5 | 19 | 42 | 67 | |

| Degree of protection | L1, L2 | 3~100 | IP65 | ||||||

| Grease | L1, L2 | 3~100 | Fully Synthetic Grease | ||||||

| Transmission inertia of reducer | |||||||||

| Size | Stage | Ratios | WABR042 | WABR060 | WABR090 | WABR115 | WABR142 | WABR180 | WABR220 |

| Moment of inertia(kg.cm) | 3 | 0.06 | 0.23 | 0.98 | 2.36 | 10.1 | 31 | 79.63 | |

| 4 | 0.06 | 0.18 | 0.68 | 1.68 | 7.3 | 26 | 59.3 | ||

| L1 | 5 | 0.06 | 0.17 | 0.66 | 1.55 | 6.58 | 23.8 | 54.86 | |

| 6/7/8 | 0.06 | 0.15 | 0.6 | 1.48 | 6.22 | 23 | 54.32 | ||

| 9/10/14/18/20 | 0.06 | 0.14 | 0.58 | 1.45 | 6.15 | 22.9 | 54 | ||

| 12/15/18/20 | 0.05 | 0.18 | 0.68 | 2.4 | 6.52 | 24.27 | 54.37 | ||

| L2 | 30/35/40 | 0.05 | 0.15 | 0.68 | 1.68 | 6.52 | 23.82 | 54.37 | |

| 45/50/70 | 0.05 | 0.15 | 0.6 | 1.51 | 6.21 | 22.94 | 53.3 | ||

| 80/90/100 | 0.05 | 0.14 | 0.6 | 1.41 | 6.1 | 22.75 | 52.45 | ||

Application Industry

Suitable for a wide range of applications

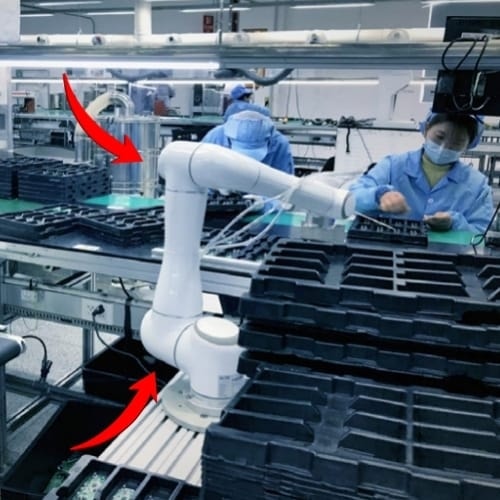

Cooperative Robot

Multi-articular machine

Laser Cutting Machine

Machine tool,Grinding mach-ines

PARALLEL MANIPULATOR

Scara robots,spider hand...

INDUSTRIAL ROBOT

Manipulator,axis robot etc

HUMANOID ROBOT

Bionic robot,walking robots

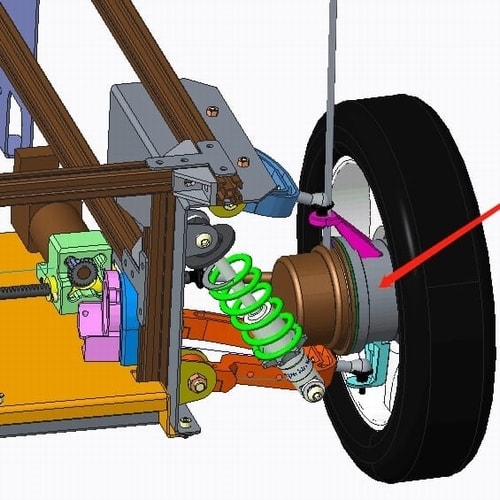

AGV CAE

Warehouse logistics AGV car

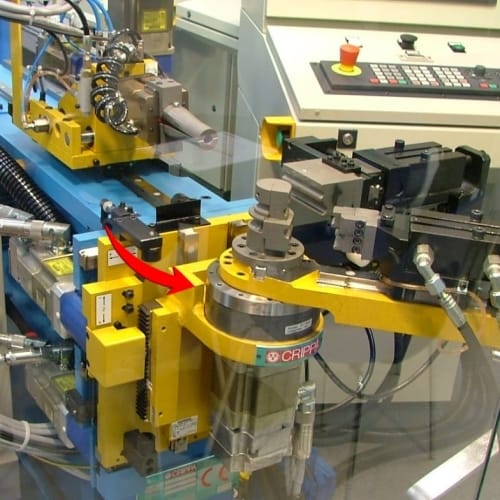

MACHINE TOOL

Pipe bending machine...

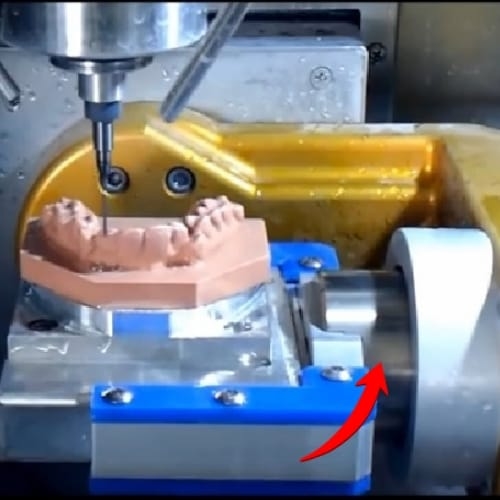

CNC Carving Machine

Denture carving and printing

EXTERNAL ROBOTS

rehabilitation bobot...

Factories of Fubao Mechanic Tech

English

English Deutsch

Deutsch Русский

Русский Español

Español

Quote Now