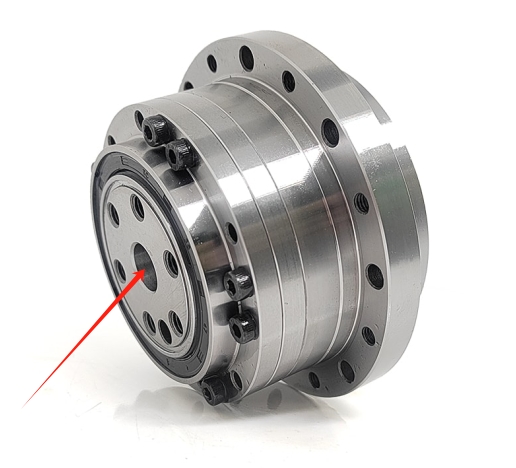

Introduction to RV Precision ReducersRV precision reducers, known for their high precision and torque density, are integral to various mechanical systems requ...

The RV (Rotary Vector) reducer, known for its precision and compact design, is a critical component in the joints of industrial robots. It enables precise an...

Performance Advantages: High Efficiency: Micro cycloidal gear reducers typically exhibit high transmission efficiency, effectively transferring input power t...

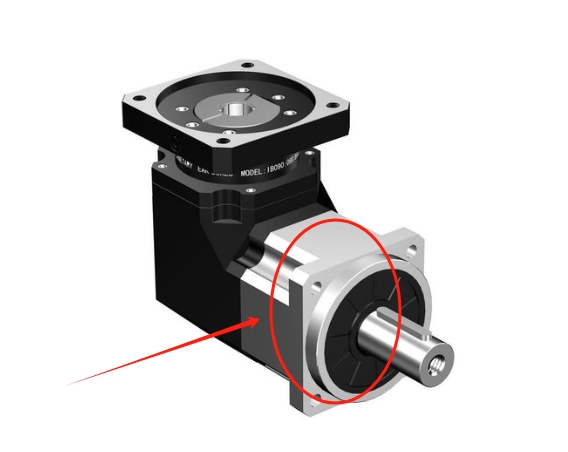

Single-stage and double-stage gearboxes, commonly referred to as single-stage and double-stage reducers, are two distinct types of gear reduction systems used...

The design of high power density for an RV (Rotary Vector) reducer is a critical aspect in the field of mechanical engineering, particularly for applications ...

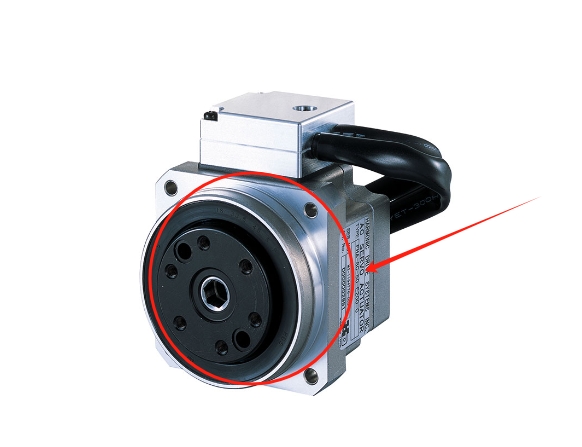

RV (Rotary Vector) reducers and Harmonic Drive reducers are two types of precision reducers widely used in industrial robotics. Both play crucial roles in the...

When it comes to gear reducers, two common types of gears used are straight or spur gears and helical gears. Both have their unique characteristics, advantage...

Selecting the appropriate gear reducer for a specific application is a critical process that requires careful consideration of various factors to ensure optim...

In the era of industry 4.0, where smart technologies and automation are reshaping the landscape of manufacturing and production, reducers play a crucial role ...

The reducer frame is a new transmission mechanism, which is based on the traditional rotating planetary pin gear. High efficiency has been widely used in industrial robot joints. The Servo engine power of industrial robot is input to the gear on the shaft by the reducer, so that the output fangs become the gear shaft, thus achieving the purpose of deceleration. The percentage of teeth and gears is the percentage of infection spread....

Fill the quantity required to get the latest price!

English

English Deutsch

Deutsch Русский

Русский Español

Español